Nail Ua Tshuab Series

-

D50 high-speed ntsia thawv ua tshuab

Peb Cov Ntsia Hlau Ua Tshuab Siab Ceev yog tsim los xa cov kev ua tau zoo tshaj plaws, ua rau cov ntsia hlau tshwj xeeb zoo ib yam. Nws cov nqi tsim khoom sai ua kom muaj peev xwm ua tau zoo, tso cai rau cov lag luam kom ua tau raws li kev xav tau ntawm kev lag luam loj hlob yam tsis muaj kev cuam tshuam rau qhov zoo lossis sijhawm xa khoom. Los ntawm cov tuam txhab tsim kho mus rau woodworking rhiav, peb lub tshuab yog lub zoo meej haum rau txhua lub lag luam uas yuav tsum tau rau tes rau lawv cov haujlwm.

-

Magnetic feeding tshuab

Magnetic loader yog cov cuab yeej tshwj xeeb rau kev xa cov khoom ferrous (xws li rau tes, ntsia hlau, thiab lwm yam) mus rau qhov chaw tshwj xeeb, uas yog siv dav hauv kev tsim khoom thiab sib dhos kab. Cov hauv qab no yog cov lus piav qhia ntxaws ntawm cov hlau nplaum loader:

Txoj Cai Ua Haujlwm

Sib nqus loading tshuab adsorbs thiab hloov cov khoom ferrous mus rau qhov chaw xaiv los ntawm cov hlau nplaum uas muaj zog los yog sib nqus conveyor siv. Lub hauv paus ntsiab lus ua haujlwm feem ntau suav nrog cov kauj ruam hauv qab no:Object adsorption: Cov khoom ferous (xws li rau tes) yog sib npaug sib npaug ntawm cov khoom siv kawg ntawm lub tshuab thauj khoom los ntawm kev vibration lossis lwm yam.

Kev sib nqus hlau nplaum: Ib lub zog hlau nplaum built-in lossis sib nqus conveyor siv adsorbs cov khoom thiab txav lawv mus rau txoj kev teeb tsa los ntawm kev siv tshuab lossis hluav taws xob.

Kev sib cais thiab tshem tawm: Tom qab ncav cuag txoj haujlwm, cov khoom raug tshem tawm los ntawm cov khoom siv hlau nplaum los ntawm cov khoom siv demagnetizing los yog txoj kev sib cais ntawm lub cev los mus rau cov txheej txheem tom ntej lossis kev sib dhos. -

Ordinary xov dov tshuab US-1000

Xov rolling tshuab yog cov khoom siv los tsim cov ntsia hlau. Muaj ntau hom xov dov tshuab, uas tuaj yeem ua tau raws li qhov xav tau sib txawv ntawm kev ua lag luam rau ntau hom ntsia thawv tsim. Xov rolling tshuab yog yooj yim, rhiab heev, muaj txiaj ntsig thiab muaj lwm yam khoom siv zoo sib xws tsis tuaj yeem hloov pauv.

-

Kev kub ceev xov dov tshuab US-3000

Xov rolling tshuab yog cov khoom siv los tsim cov ntsia hlau. Muaj ntau hom xov dov tshuab, uas tuaj yeem ua tau raws li qhov xav tau sib txawv ntawm kev ua lag luam rau ntau hom ntsia thawv tsim. Xov rolling tshuab yog yooj yim, rhiab heev, muaj txiaj ntsig thiab muaj lwm yam khoom siv zoo sib xws tsis tuaj yeem hloov pauv.

-

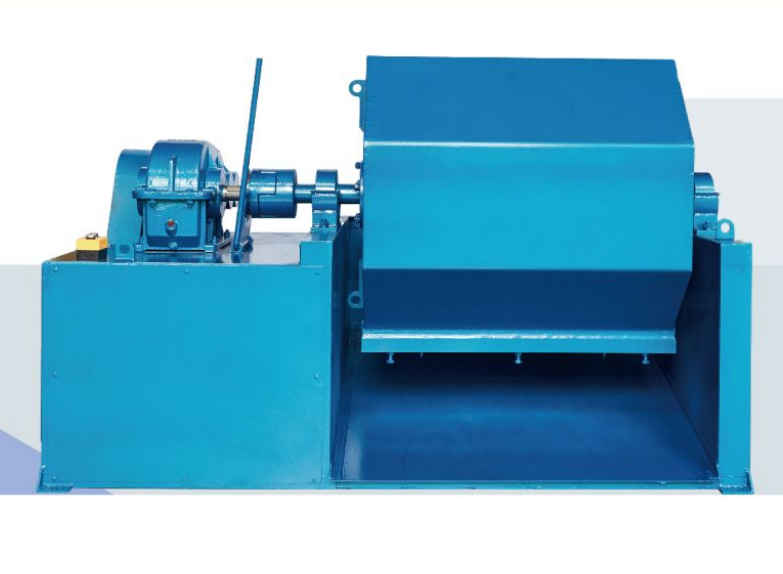

Ntsia tshuab ntxhua khaub ncaws

Lub tshuab ntsia hlau ntsia hlau tseem hu ua ntsia thawv tshuab ntxhua khaub ncaws. Nws tshem tawm cov burrs thiab polishes cov ntsia hlau ua tiav los ntawm cov ntsia hlau ua tshuab los ntawm kev kub ceev rotating kev sib txhuam, thiab yog siv los derust thiab polish lub semi-tiav round ntsia hlau nyuam qhuav tsim. Tus ntsia thawv polishing tshuab yog ib qho khoom siv tshwj xeeb uas tsis tseem ceeb hauv kev lag luam ntsia thawv.

Cov rau tes yog qias neeg nrog qee cov roj thaum poob los ntawm cov ntsia hlau ua tshuab txiav. Tsis tas li ntawd, ntau cov huab cua hauv cov ntsia hlau ua cov nroj tsuag. Yog li peb xav tau ibhlau ntsia thawv polishing tshuabua kom cov hlau ntsia hlau ntau ci ntsa iab.

-

Bright Hlau Ncaj Kab Hlau Drawing Tshuab

Technical Specifications Loj Max inlet Min qhov hluav taws xob kos duab Tus Nqi Nruab Nrab Qhov Nruab Nrab Tus Nqi Them Nqi Tshaj Tawm Max Ceev Lub Cev Lub Hwj Chim Lub Hwj Chim Lub Hwjchim Lub Hwjchim Tsis Txaus Ntsig Ntsig Φ1200 Φ8mm Φ5.0mm 1-9 ≤ 20% 60% 120M / min 90KW 132KW 80db 0mm 6mm ≤ 20% 60% 240M/min 75KW 110KW 80db 60% Φ700 Φ8mm Φ2.6mm 4-13 ≤ 20% 60% 600M/min 30KW 45KW 80db 70mm 4mm Φ1 0% 60% 720M / min 18.5KW 37KW 81db 80% TSI... -

Kab rov tav / Vertical Spooler

tso cai rau sau cov xaim ntawm lub spooler. Nws tau muab nrog cov lus qhia xaim ntawm cov suab sib txawv.

-

Npuag Hlau Drawing Tshuab

Npuag Hlau Drawing Tshuab

Haum rau kev kos cov hlau muaj zog, xws li lub log tsheb, PV silicon txiav hlau

-

Ncaj-Line Hlau Drawing Tshuab LZ-900-1000-12000

Hlau Drawing tshuab yog dav siv nyob rau hauv kev lag luam kev siv, dav siv nyob rau hauv machinery manufacturing, hardware processing, petrochemicals, yas, xyoob thiab ntoo khoom, hlau thiab cable thiab lwm yam lag luam.

-

Ncaj-Line Hlau Drawing Tshuab LZ-350-400

Hlau Drawing tshuab yog dav siv nyob rau hauv kev lag luam kev siv, dav siv nyob rau hauv machinery manufacturing, hardware processing, petrochemicals, yas, xyoob thiab ntoo khoom, hlau thiab cable thiab lwm yam lag luam.

-

Ncaj-Line Hlau Drawing Tshuab LZ-200-250-300

Hlau Drawing tshuab yog dav siv nyob rau hauv kev lag luam kev siv, dav siv nyob rau hauv machinery manufacturing, hardware processing, petrochemicals, yas, xyoob thiab ntoo khoom, hlau thiab cable thiab lwm yam lag luam.

-

Sib nqus feeder

Txheej txheem piav qhia:Lub workpiece yog poured rau hauv kuv lub hopper (nrog lub caij nplooj ntoos hlav) los ntawm cov khoom thav duab, thiab muaj ib tug vibration ntaus ntawv nyob rau hauv lub hopper. Cov cuab yeej vibration ua haujlwm kom sib npaug ntawm cov khoom ua haujlwm hauv lub hopper ntawm txoj siv conveyor. Muaj ib qho chaw sib nqus muaj zog nyob rau sab nraum qab ntawm txoj siv conveyor, uas nqus cov khoom ua haujlwm los ntawm kev khiav raws cov kab liab liab mus rau sab saum toj. Thaum cov hlau nplaum muaj zog nce mus txog rau saum toj, nws tau rov ua dua, thiab lub workpiece poob rau hauv lub dav hlau ua haujlwm tom ntej ntawm cov txheej txheem.