Lwm lub tshuab

-

Blocks Multi Rip Saw

Blocks Multi Rip Saw yog tsim rau txiav chip pallets, khoom ntoo, ntau txheej ntoo, nws dominates ntoo vaj huam sib luag ua cov cuab yeej, lub tshuab no muaj cov yam ntxwv ntawm kev ua haujlwm ruaj khov, ntau lawm, kev ua haujlwm zoo thiab kev saib xyuas yooj yim.

Qhov Blocks Multi Rip Saw yog qhov yooj yim thiab yooj yim rau kev khiav lag luam, lub tshuab muaj plua plav tsawg thiab cov hmoov av zoo heev thaum txiav ntoo.

-

Rotary hom tshuab ziab khaub ncaws

Lub tshuab ziab khaub ncaws tshwj xeeb rau cov chips ntoo yog tsim thiab tsim rau ziab sawdust, me me ntoo chips thiab ntoo veneer. Nws yog tus cwj pwm los ntawm kev ziab kom qhuav, zoo kawg nkaus lub zog-txuag nyhuv thiab kev saib xyuas qis. Lub hauv paus ntsiab lus ntawm kev ua haujlwm yog: ntoo chips nkag mus rau hauv lub nruas teb los ntawm lub tshuab raj thiab lub tog raj kheej lub tog raj kheej ua ke, cov khoom siv hauv lub tog raj kheej boiling fluidization, cua kub thiab cov khoom siv tag nrho kov, ua kom qhuav.

-

Tov khoom

Txawb me me tov khoom tig lub teeb thiab siv tau yooj yim, siv ib-theem reducer lub cev muaj zog, yooj yim siv hluav taws xob, tsuav yog muaj lub teeb pom kev zoo ntawm tus cwj mem tuaj yeem txuas rau siv. Cov khoom sib xyaw ua ke yog ua los ntawm cov hlau tsis muaj zog tsis muaj xeb, yog li koj tsis tas yuav txhawj xeeb txog xeb thiab paug cov khoom noj los ntawm kev sib xyaw fermented pub. Ua ke nrog cov qauv tsim tshwj xeeb ntawm rab riam nplawm, kom ua tiav cov ntaub ntawv raw hauv lub thoob tumbling ceev, nplawm kom ua tiav qhov kawg-kawg, ua kom tiav cov tsoos tov khoom thoob hauv qab ntawm lub neej ntawm kev tuag-kawg sib tov tsis sib haum. , siab sib xyaw uniformity, nyob rau hauv lub tov khoom ntxiv cov tshuaj tiv thaiv thiab pub additives tsis muaj kev txhawj xeeb txog kev sib xyaw cov tshuaj tsis sib xws. Txawm hais tias cov qauv sib tov me me, tab sis kev teeb tsa ntawm lub reducer lub cev muaj zog sib xyaw ua ke muaj zog heev, sib xyaw ua haujlwm zoo thiab muaj zog.

-

Pipes Tshuab ziab khaub ncaws

Lub thiaj li hu ua airflow drying yog hais txog cov ntub sawdust nyob rau hauv daim ntawv ntawm cov hmoov thiab granule, uas yog txuas ntxiv mus rau hauv lub tshuab ziab khaub ncaws los ntawm cov ntsia hlau conveyor. Nyob rau hauv lub high-ceev cua kub conveying thiab dispersion, kom cov dej noo nyob rau hauv cov ntaub ntawv ntub dej evaporation, tau hmoov los yog granular qhuav khoom txheej txheem. Nws yog tsim los ntawm cov cua kub cua sov, feeder, airflow drying tube, cyclone separator, kiv cua thiab lwm yam.

-

Ntoo Block Presser

Ntoo Block Presser tsuas yog siv cov shavings, ntoo chips thiab lwm yam khoom pov tseg, los ntawm kev sib xyaw nrog cov kua nplaum sib piv, los ntawm kev ziab, gluing, kub xovxwm cua sov thiab siab los tsim shavings, ntoo chips ko taw pier, nto yog du thiab du, zoo waterproof ( tsau dej 48 teev yam tsis tau tawg, cua khawb thiab tshav ntuj tsis tawg). Cov cuab yeej siv tau yooj yim, yooj yim rau kev khiav lag luam, tsim cov ntaub qhwv ntoo huv si thiab ib puag ncig tus phooj ywg, kev lag luam dav dav, raws li txoj cai kev lag luam hauv teb chaws. Nws yog ib qho tsim nyog yuav tau xyuam xim rau: koj yuav tsum hnav tsom iav thaum ua haujlwm kom muaj kev nyab xeeb.

-

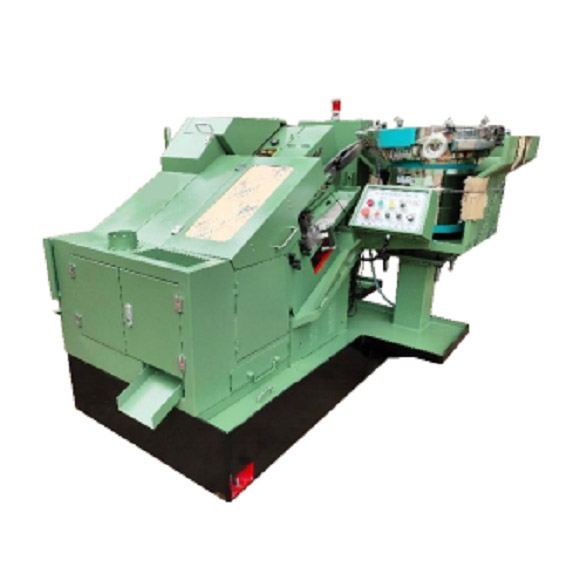

Self Drilling Screw Xov Rolling Tshuab

Kev Ua Tau Zoo: Cov ntsia hlau xov dov tshuab txo cov nqi tsim khoom los ntawm kev nias ncaj qha yam tsis muaj txheej txheem txiav thiab ua tsis muaj pov tseg. Kev tsim khoom siab ntawm lub tshuab ua kom muaj kev sib luag ntawm cov xov tiav thiab raug.

Enhanced Strength: Piv nrog rau cov txheej txheem txiav ib txwm, xov dov txheej txheem tsim cov xov nrog lub zog ntau dua thiab cov khoom siv ruaj khov dua, uas tsim nyog rau ntau yam kev lag luam.

-

Self Drilling Screw Point Forming Tshuab

Tus Tsov tus tw ntawm lub laum tail screw yog nyob rau hauv cov duab ntawm ib tug laum tail los yog ib tug taw tes tail. Nws tsis tas yuav tho qhov ntawm lub workpiece ua ntej, thiab tuaj yeem xyaum ncaj qha, kais, thiab xauv rau ntawm qhov chaw thiab cov khoom siv hauv paus. Piv nrog rau cov ntsia hlau zoo tib yam, lub laum tail screw High tenacity thiab tuav lub zog, nws yuav tsis xoob tom qab lub sijhawm ntev ntawm kev sib xyaw ua ke, yooj yim thiab nyab xeeb siv, drilling thiab tapping tuaj yeem ua tiav hauv ib qho haujlwm, txuag lub sijhawm, kev ua haujlwm thiab kev ua haujlwm. Drilling screws feem ntau yog siv los kho cov hlau phaj xws li steel phaj fasteners, feem ntau yog siv los xauv cov hlau phaj thiab cov hlau tsis yog hlau, xws li rau kev kho ncaj qha silicon-calcium boards, gypsum boards thiab ntau yam ntoo boards ntawm cov hlau phaj. Drilling screws nrog tsim tsim nyog thiab cov qauv tuaj yeem ua rau cov phaj hlau thiab cov phaj mating nruj nreem kaw, tsis txhob muaj kev puas tsuaj thiab khawb ntawm cov phaj mating, thiab yooj yim rau nruab.

-

USGT 6-12 NC Steel Bar Straightening Tej Tshuab

Main siv los txiav round bar straightening thiab txiav, siv raws li hauv qab no:

Rau txias dov ribbed steel tuav rau kev tsim kho, kub dov steel, txias dov du nto puag ncig bar, kub dov rebar, round bar, thiab lwm yam.

-

UST 4-10 NC Steel Bar Straightening Tej Tshuab

1. Ncaj thiab txiav steel bar dia: ¢8-¢10mm

2. Txiav ntev: 0.75m-6m3. ceev: 50m / min

3. Tso zis (txhua 8 teev): ¢6(4-5tons); 8 (6-8 tons); ¢10 (8-10tons)

4. Input batches ib txhij: 1-20batches

5. Ib qho batch txiav daim: 1-9999. Ntev ntev: ± 3-4mm

6. Lub zog: 50HZ

7. CNC lub thawv fais fab: ≤14w

8. Ntim: 2500 × 700 × 1300mm

-

Tag nrho Automation thiab siv tsawg Clip ntsia thawv ua tshuab

Lub tshuab no yog tsim los ntawm peb lub tuam txhab raws li cov txheej txheem ntawm cov ntsia hlau clipping tshuab cov cuab yeej thiab cov cuab yeej txhawb nqa.Nws pab cov txheej txheem tsim los ntawm kev ua haujlwm huv huv mus rau tag nrho automation.Nws muaj txiaj ntsig zoo thiab tuaj yeem pab koj txo nqi zog.