Cov khoom

-

Yas Sawb Nails

Zoo ntsia thawv fastening nyhuv, kev ua haujlwm yooj yim, kev nyab xeeb siab hauv kev siv.

Cov qauv ntawm cov ntsia hlau ntsia hlau yog liab qab lub cev, kauv, nplhaib qauv. -

Self Drilling Screw Heading Tshuab

Screw heading tshuab yog ib yam khoom siv txias taub hau rau kev tsim cov ntsia hlau, uas yog cov hlau ua tshuab rau cov ntsia hlau yooj yim. Muaj zog yooj thiab yooj yim hloov qhov ntev yog haum rau me me batch ntau lawm los yog proofing. Kev tawm los thiab kev ua tau zoo yog cuam tshuam ncaj qha rau cov neeg ua haujlwm. Screw forming Muaj ob hom ntsia hlau sib sau thiab xov sib sau: cov cuab yeej siv rau kev sib sau ua ke yog lub taub hau tshuab, uas siv cov txheej txheem txias thiab sib sau; cov cuab yeej siv rau kev sib sau xov yog lub tshuab ua hniav, uas siv cov txheej txheem extrusion thiab sib sau. Nws muaj qhov zoo ntawm qhov chaw zoo dua thiab siab dua qhov tseeb. Vim lub txias ua hauj lwm hardening nyob rau hauv cov txheej txheem chim siab, tus nqi ntawm deformation yuav tsum tsis txhob loj heev txo cracking.

-

D50 high-speed ntsia thawv ua tshuab

Peb Cov Ntsia Hlau Ua Tshuab Siab Ceev yog tsim los xa cov kev ua tau zoo tshaj plaws, ua rau cov ntsia hlau tshwj xeeb zoo ib yam. Nws cov nqi tsim khoom sai ua kom muaj peev xwm ua tau zoo, tso cai rau cov lag luam kom ua tau raws li kev xav tau ntawm kev lag luam loj hlob yam tsis muaj kev cuam tshuam rau qhov zoo lossis sijhawm xa khoom. Los ntawm cov tuam txhab tsim kho mus rau woodworking rhiav, peb lub tshuab yog lub zoo meej haum rau txhua lub lag luam uas yuav tsum tau rau tes rau lawv cov haujlwm.

-

3-axis CNC ob lub taub hau chamfering thiab npav tshuab

Tsis siv neeg ob lub taub hau chamfering tshuab lub clamping tuag thiab cutter phaj, tom qab exquisite tsim, los xyuas kom meej tias cov kab nruab nrab ntawm cov khoom thiab cov cutter phaj yog raug thiab tsis hloov, yuav ua tau uniformly tiav nyob rau hauv ib lub sij hawm, los xyuas kom meej cov kev ua tau zoo. loj, los ntawm kev vibration phaj tsis siv neeg thauj khoom, zoo heev txhim kho kev tsim khoom thiab txuag cov neeg ua haujlwm.

-

Daim ntawv strip rau tes

Ntev:110mm-160mm

Lub hom phiaj: Tsim nyog rau kev kho kom zoo nkauj, kev teeb tsa ntawm cov khoom ntoo, kho cov thawv ntim khoom.

-

Qhob Nailer

Nrog harden kho magazine, ua rau kev pab lub neej ntev.

Kev ruaj khov fring pin pab pawg thiab O-ring. Lub zog muaj zog, thiab ceev cua-rov qab.

Phom lub cev ntxiv dag zog rau kev kho cua sov yog qhov ruaj khov, ruaj khov thiab nyab xeeb 12.9 lub zog siab rau lub kaum ntse ntse, ruaj khov.

-

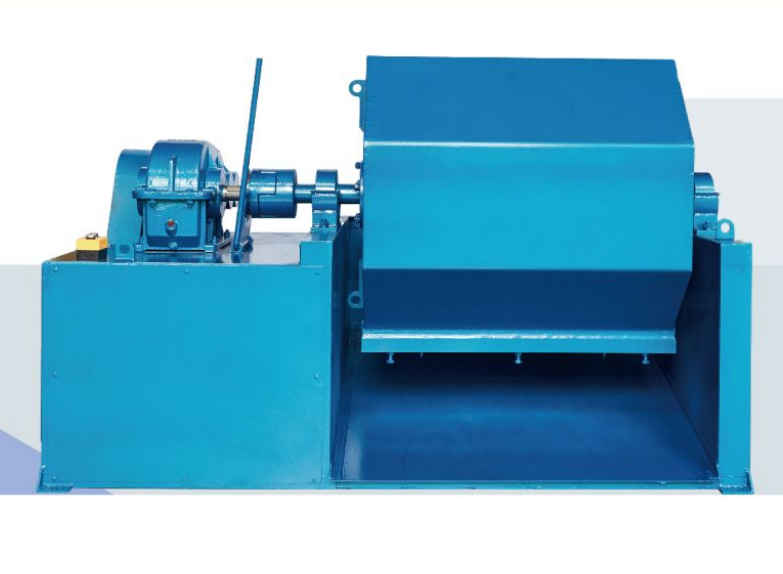

Magnetic feeding tshuab

Magnetic loader yog cov cuab yeej tshwj xeeb rau kev xa cov khoom ferrous (xws li rau tes, ntsia hlau, thiab lwm yam) mus rau qhov chaw tshwj xeeb, uas yog siv dav hauv kev tsim khoom thiab sib dhos kab. Cov hauv qab no yog cov lus piav qhia ntxaws ntawm cov hlau nplaum loader:

Txoj Cai Ua Haujlwm

Sib nqus loading tshuab adsorbs thiab hloov cov khoom ferrous mus rau qhov chaw xaiv los ntawm cov hlau nplaum uas muaj zog los yog sib nqus conveyor siv. Lub hauv paus ntsiab lus ua haujlwm feem ntau suav nrog cov kauj ruam hauv qab no:Object adsorption: Cov khoom ferous (xws li rau tes) yog sib npaug sib npaug ntawm cov khoom siv kawg ntawm lub tshuab thauj khoom los ntawm kev vibration lossis lwm yam.

Kev sib nqus hlau nplaum: Ib lub zog hlau nplaum built-in lossis sib nqus conveyor siv adsorbs cov khoom thiab txav lawv mus rau txoj kev teeb tsa los ntawm kev siv tshuab lossis hluav taws xob.

Kev sib cais thiab tshem tawm: Tom qab ncav cuag txoj haujlwm, cov khoom raug tshem tawm los ntawm cov khoom siv hlau nplaum los ntawm cov khoom siv demagnetizing los yog txoj kev sib cais ntawm lub cev los mus rau cov txheej txheem tom ntej lossis kev sib dhos. -

Ordinary xov dov tshuab US-1000

Xov rolling tshuab yog cov khoom siv los tsim cov ntsia hlau. Muaj ntau hom xov dov tshuab, uas tuaj yeem ua tau raws li qhov xav tau sib txawv ntawm kev ua lag luam rau ntau hom ntsia thawv tsim. Xov rolling tshuab yog yooj yim, rhiab heev, muaj txiaj ntsig thiab muaj lwm yam khoom siv zoo sib xws tsis tuaj yeem hloov pauv.

-

Kev kub ceev xov dov tshuab US-3000

Xov rolling tshuab yog cov khoom siv los tsim cov ntsia hlau. Muaj ntau hom xov dov tshuab, uas tuaj yeem ua tau raws li qhov xav tau sib txawv ntawm kev ua lag luam rau ntau hom ntsia thawv tsim. Xov rolling tshuab yog yooj yim, rhiab heev, muaj txiaj ntsig thiab muaj lwm yam khoom siv zoo sib xws tsis tuaj yeem hloov pauv.

-

Ntsia tshuab ntxhua khaub ncaws

Lub tshuab ntsia hlau ntsia hlau tseem hu ua ntsia thawv tshuab ntxhua khaub ncaws. Nws tshem tawm cov burrs thiab polishes cov ntsia hlau ua tiav los ntawm cov ntsia hlau ua tshuab los ntawm kev kub ceev rotating kev sib txhuam, thiab yog siv los derust thiab polish lub semi-tiav round ntsia hlau nyuam qhuav tsim. Tus ntsia thawv polishing tshuab yog ib qho khoom siv tshwj xeeb uas tsis tseem ceeb hauv kev lag luam ntsia thawv.

Cov rau tes yog qias neeg nrog qee cov roj thaum poob los ntawm cov ntsia hlau ua tshuab txiav. Tsis tas li ntawd, ntau cov huab cua hauv cov ntsia hlau ua cov nroj tsuag. Yog li peb xav tau ibhlau ntsia thawv polishing tshuabua kom cov hlau ntsia hlau ntau ci ntsa iab.

-

Bright Hlau Ncaj Kab Hlau Drawing Tshuab

Technical Specifications Loj Max inlet Min qhov hluav taws xob kos duab Tus Nqi Nruab Nrab Qhov Nruab Nrab Tus Nqi Them Nqi Tshaj Tawm Max Ceev Lub Cev Lub Hwj Chim Lub Hwj Chim Lub Hwjchim Lub Hwjchim Tsis Txaus Ntsig Ntsig Φ1200 Φ8mm Φ5.0mm 1-9 ≤ 20% 60% 120M / min 90KW 132KW 80db 0mm 6mm ≤ 20% 60% 240M/min 75KW 110KW 80db 60% Φ700 Φ8mm Φ2.6mm 4-13 ≤ 20% 60% 600M/min 30KW 45KW 80db 70mm 4mm Φ1 0% 60% 720M / min 18.5KW 37KW 81db 80% TSI... -

GALVANIZED FIELD FENCE

Khoom siv: CARBON STEEL Q195

APPLICATIONS:FACILITATE LUB PLANNED siv GRASSAV RESOURCES THIAB YUAV TSUM PAUB TXOG KEV SIV NYIAJ THIAB GRAZING EFFICIENCY.Tam sim tib lub sijhawm, nws kuj tseem siv tau rau kev tsim tsev neeg

THAJ CHAW NROG UA HAUJ LWM THIAB HAIV NEEG, LUB SIJ HAWM NTAWM TXOJ CAI NTAWM TXOJ CAI NTAWM TXOJ CAI, KEV UA HAUJ LWM HAUJ LWM, HAIV NEEG, KEV KAWM NTAWV, TXOJ HAUJ LWM RAU HAUV PAUS, KEV PAB CUAM TIV THAIV THIAB TIV THAIV KEV PAB CUAM, THIAB KEV PAB CUAM.