Z12 Series 1-Tuag 2-Blow Cold Heading Tshuab

1. Lub tshuab tseem ceeb thav duab thiab ram thiab lwm yam tau raug kho kom sov rau kev tso cov kev ntxhov siab sab hauv thiab normalized tom qab casting kom tsis txhob muaj deformation nyob rau hauv lub sij hawm ntev ua hauj lwm thiab ua kom ib tug ruaj khov precision.

2. Cov menyuam txiav tawm tau txais kev txhawb nqa ntawm ob sab kom tau txais qhov siab tshaj plaws rigidity thiab ruaj khov txiav.

3. Ib qho yooj yim thiab tsim nyog tsim kom nqus tau qhov nce thiab nqis txav ntawm cov punch slider nrog kev hloov kho sai thiab kev saib xyuas yooj yim.

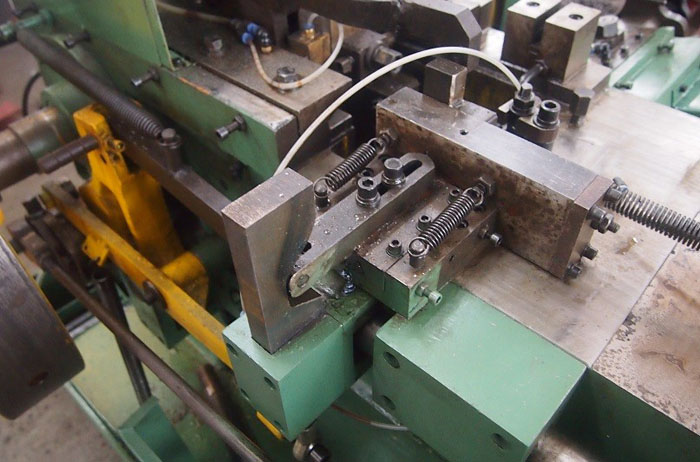

4. Overam hom lub ntsiab slider nrog liners ua los ntawm high alloy steel pub ntev thiab ruaj khov precision. PKO tiv thaiv spill-out ntawm forged qhov chaw los ntawm kev tsim tuag ua ntej yuav khob tawm.

5. Kev ruaj ntseg pins yog siv rau khob tawm thiab txiav tawm mechanism los tiv thaiv kev puas tsuaj ntawm lub tshuab qhov chaw.

6 "Inching", "Single Stroke" thiab "Nruam Khiav" ua kom sib haum ntawm lub tshuab nrog cov cuab yeej yooj yim heev.

7. PLC tswj xyuas kev nyab xeeb tuaj yeem saib xyuas kev ua haujlwm ntawm lub kaw lus tseem ceeb thiab tso saib thiab ceeb toom qhov txawv txav.

| Qauv | Qhov siab tshaj plaws | Qhov ntev tshaj plaws | Ram Stroke | Output Rate | Main Mould | Txiav-off Tuag | Pnch Tuag | Cutter Loj | Mechanical Dimesions | Main Tsav | Net nyhav |

| Z12-3 | 4 | 20 | 40 | 160-190 : kuv | φ20 * 36 | φ13 * 25 | φ18 * 50 | 6 * 25 * 42 | 1.4 * 0.75 * 0.9 hli | 1.1 | 624 ib |

| Z12-4 | 5 | 40 | 60 | 140-170 : kuv | Loj: 32 * 60 | φ15 * 30 | φ25 * 65/70 | 10 * 35 * 72 | 1.8 * 0.85 * 1.5 hli | 2.2 | 1274 ib |

| Z12-5 | 7 | 60 | 90 | 110-140 : kuv | Loj: 32 * 80 | φ20 * 35 | Loj: 30 * 75 | 10 * 35 * 72 | 2.3 * 1.08 * 1.25 | 3 | 2080 |

| 80 | 110 | 90-110 : kuv | φ32 * 100 | φ20 * 35 | Loj: 30 * 80 | 10 * 35 * 72 | 2.4 * 1.15 * 1.35 hli | 2145 ib | |||

| 100 | 130 | 80-100 | φ35 * 120 | φ20 * 35 | Loj: 30 * 80 | 10 * 35 * 72 | 2.5 * 1.15 * 1.35 hli | 2210 | |||

| 150 | 190 | 80-100 | Loj: 40 * 180 | φ20 * 35 | φ35 * 100 | 10 * 35 * 72 | 2.6 * 1.15 * 1.35 hli | 2990 ib | |||

| Z12-6 | 9 | 90 | 120 | 80-100 | Loj: 50 * 120 | φ24 * 40 | φ35 * 100 | 12 * 35 * 77 hli | 2.7 * 1.4 * 1.6 | 5.5 | ib 3380 |

| 120 | 150 | 70-90 : kuv | φ50 * 150 | φ24 * 40 | φ35 * 100 | 12 * 35 * 77 hli | 2.8 * 1.4 * 1.6 | ib 3640 | |||

| 150 | 190 | 60-70 ib | Loj: 50 * 180 | φ24 * 40 | φ35 * 100 | 12 * 35 * 77 hli | 3.0 * 1.4 * 1.6 | ib 4160 | |||

| 170 | 230 | 50-60 | Loj: 50 * 220 | φ24 * 55 | φ35 * 120 | 12 * 35 * 77 hli | 3.2 * 1.4 * 1.6 | ib 4360 | |||

| 200 | 250 | 40-50 | Loj: 50 * 240 | φ24 * 55 | φ35 * 120 | 12 * 35 * 77 hli | 3.65 * 1.4 * 1.65 hli | ib 4940 | |||

| 250 | 290 | 30-45 : kuv | Loj: 50 * 290 | φ24 * 60 | Loj: 35 * 140 | 12 * 35 * 77 hli | 3.7 * 1.5 * 1.7 hli | ib 5460 | |||

| Z12-8 | 11 | 120 | 160 | 60-80 | Loj: 60 * 160 | Loj: 28 * 45 | φ40 * 120 | 12 * 42 * 90 | 3.75 * 1.6 * 1.8 hli | 7.5 | ib 4940 |

| 150 | 190 | 60-70 ib | Loj: 60 * 190 | Loj: 28 * 45 | φ40 * 120 | 12 * 42 * 90 | 3.9 * 1.6 * 1.8 | ib 6240 | |||

| 200 | 250 | 40-50 | Loj: 60 * 240 | Loj: 28 * 60 | φ40 * 150 | 12 * 42 * 90 | 4.15 * 1.6 * 1.85 hli | 6 500 | |||

| 250 | 290 | 30-45 : kuv | Loj: 60 * 290 | Loj: 28 * 60 | φ40 * 150 | 12 * 42 * 90 | 4.3 * 1.6 * 1.9 | 7800 ib | |||

| Z12-10 | 13 | 120 | 160 | 50-60 | Loj: 80 * 160 | φ35 * 50 | φ50 * 150 | 16 * 55 * 115 hli | 4.8 * 1.8 * 1.32 hli | 11 | 8450 ua |

| 180 | 230 | 50-60 | Loj: 80 * 220 | φ35 * 50 | φ50 * 150 | 16 * 55 * 115 hli | 4.8 * 1.8 * 1.32 hli | ib 8650 | |||

| 220 | 270 | 40-50 | Loj: 80 * 260 | φ35 * 50 | φ50 * 150 | 16 * 55 * 115 hli | 5.0 * 1.8 * 1.32 hli | 9100 ib | |||

| Z12-12 | 15 | 150 | 190 | 40-50 | φ88 * 200 | Loj: 45 * 60 | Loj: 60 * 180 | 18 * 60 * 125 hli | 5.2 * 1.9 * 1.8 | 18.5 Nws | ib 14040 |

| 200 | 250 | 30-40 | Loj: 88 * 260 | Loj: 45 * 60 | Loj: 60 * 180 | 18 * 60 * 125 hli | 5.2 * 1.9 * 1.8 | 14300 Nws | |||

| 280 | 330 | 30-40 | Loj: 88 * 340 | Loj: 45 * 60 | Loj: 60 * 180 | 18 * 60 * 125 hli | 5.2 * 1.9 * 1.8 | 15600 Nws | |||

| 300 | 350 | 25-35 | Loj: 88 * 360 | Loj: 45 * 60 | Loj: 60 * 180 | 18 * 60 * 125 hli | 5.2 * 1.9 * 1.8 | ib 15860 |